Certain products have an option to add a Spot UV clear varnish shape onto areas of your design.

How to supply us your Spot UV elements

Simply supply us your Spot UV shapes filled in spot colour 'SPOT-UV' on page 3 of your PDF.

OR the instructions below detail how to set up the colour yourself:

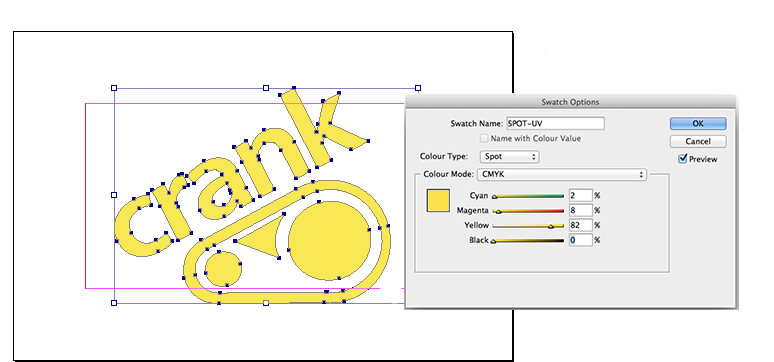

1. Create a New Colour Swatch

2. Name the swatch 'SPOT-UV' (must be exact)

3. Set Colour Type to Spot

4. Set Colour Mode to CMYK

5. Colour Make-up of SPOT-UV is 2% Cyan, 8% Magenta, 82% Yellow and 0% Black (must be exact)

6. Set swatch to Overprint (Window > Output > Attributes)

If you have Spot UV on both sides of your design, then add the Spot UV for the reverse onto a 4th page in the PDF.

Design with a little tolerance for mis-registration

The UV varnish is applied using a screen printing process, and registration with print can vary by ±2 mm. This means you should expect the Spot UV element to move around the page by up to ±2 mm.

If you are aiming to cover a printed shape having a hard edge, then the Spot UV shape should overlap the printed edge by 2 mm to allow for any inherent variations in registration. Likewise, block shapes meeting the edge should be treated like backgrounds: bleed them to the very edge of the document page, and respect the Quiet Zone.

Don't try to align fine detail

Spot UV is not suited to alignment with fine detail, such as small type, or shapes with thin lines.

Our rule of thumb:

- 1. avoid positive lines thinner than 1 mm, and

- 2. avoid reversed-out lines thinner than 2 mm.

This includes the counters, stroke widths and serifs on fonts.

You’ll get best results when you don’t try to match the Spot UV to printed objects, and instead treat it as a design element in its own right. Seperate Embossed elements should have a minimum spacing of 2mm. Placing elements too close to each other will result in them becoming one shape and filling in.

Avoid large Spot UV areas over the edge

Try to avoid large solid areas of Spot UV bleeding to the edge as chipping and flaking may occur once the job has been guillotined or die-cut.

Vectors only for Spot UV

Spot UV elements must be supplied in vector format; any text shapes to be spot-varnished must be converted to paths/outlines.

Solid varnish only; no tints

Spot UV cannot be specified as a gradient or tint, i.e. a changing tint from 100% to 0% over an area of artwork.